When it comes to cleanroom mopping systems there is a lot of choice available in the market and our Business Development Manager, Sharon frequently gets asked what she thinks is the best system. The answer is, it depends on what you are trying to achieve in the cleanroom. Here, she talks us through why.

You may not realise this, but the mopping system and the application are just as important as choosing the right cleaning chemistry for a successful cleaning and disinfection regime. Over recent years there have been major innovations from the leading manufacturers so it may be time to review your mopping SOPs to see if you can benefit from newer best practice methods.

Factors such as size, grade or class of the cleanroom, the available storage space you have and what contamination is your biggest risk are all important factors for consideration. For example, in an area with a high air change rate, can the area stay wet long enough to provide the kill time needed to provide sufficient disinfection?

The cost of selecting the right mopping system is important but cannot be the driver for selection. After the initial investment of building the cleanroom, maintaining the environment and the mitigation of risk to the final product has to be the driver of products selected.

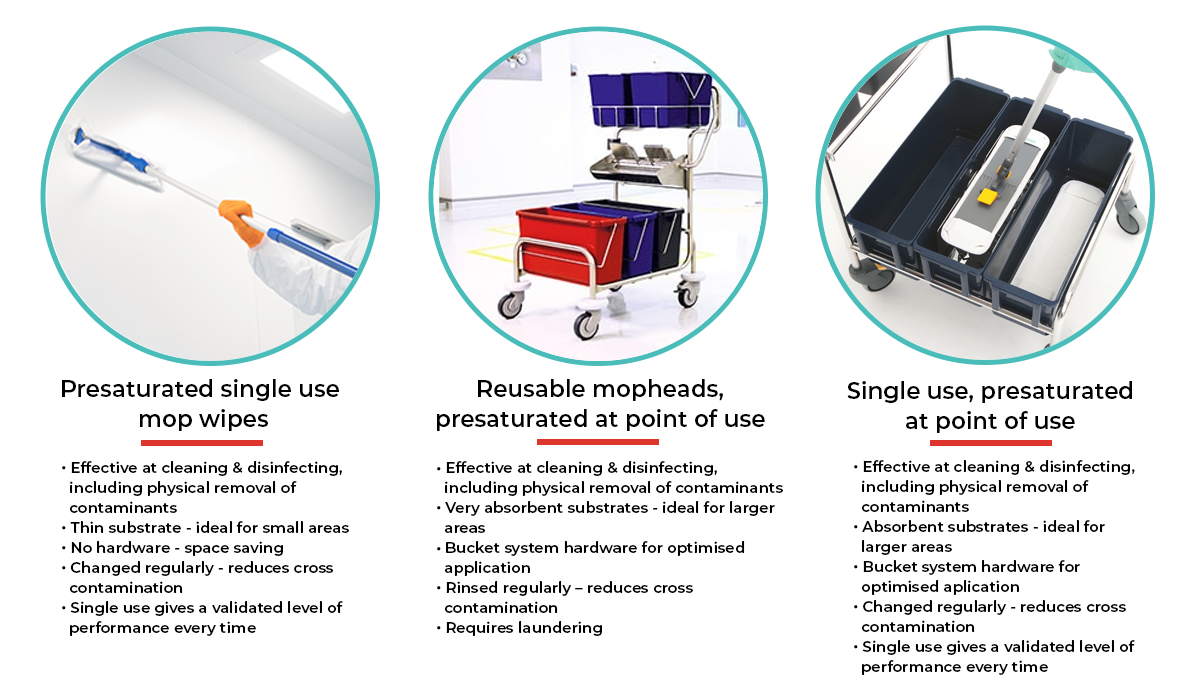

Presaturated single use mop wipes

Presaturated single use mop wipes have many advantages for smaller areas. They provide a predictable and consistent level of performance as wipes are ready to use. With a thin substrate, the mop wipes are not very absorbent so need to be changed regularly to ensure they leave enough detergent to deliver the required contact times. A mophead will be needed to ensure there is sufficient contact between the wipe and the floor, but aside from that, no other hardware is needed. The regular changing of wipes means they are effective for removing physical contamination.

Multi bucket cleaning systems

Mopheads, presaturated at the point of use with a multi bucket cleaning system is probably the most traditional mopping method. With triple bucket systems, a controlled dose of detergent can be applied to the floor, then the act of rinsing the mop facilitates the physical removal of contamination prior to reloading it with the disinfection agent. This reduces the risk of cross contamination by maximising the opportunities to remove physical contamination as well as disinfecting. Care must be taken to ensure the detergent does not weaken throughout application, but this is achievable when validating the process.

This method does have its pitfalls, as the construction of the microfibre which make the mops excellent at picking up dirt, also makes them difficult to properly clean. They are also subject to degradation over time due to the exposure of high temperatures during the autoclaving process. This is why many organisations are now moving to single-use mopheads with a bucket system. With these systems, single-use mopheads are presaturated at the point of use with a detergent and changed when needed to give a validated level of performance.

Cleanroomshop supply Ecolab, Hydroflex and Vileda mopping systems. You can browse the range online or contact us if you’d like to speak to us about your requirements.